our location

1340 Reynolds Ave #120, Irvine, CA 92614, USA

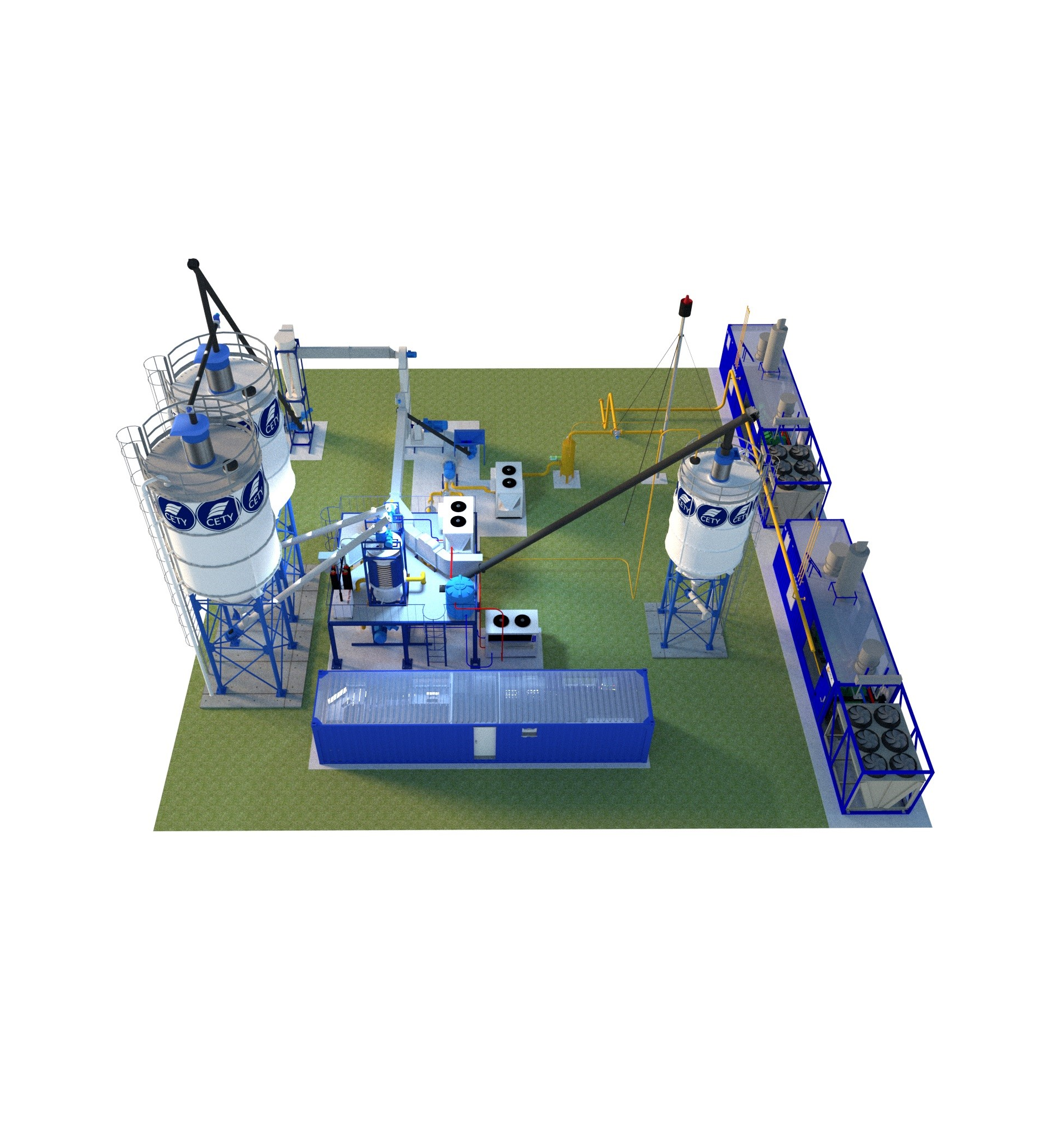

A suite of zero-emission solutions

Heat-to-power, and waste-to-energy products as well as engineering and manufacturing solutions focused on other energy efficient and environmentally sustainable technologies.

Waste to Energy

Waste, disposal, transport, and/or storage of the same has long been a challenge and now it is becoming increasingly expensive. There are now large systems implemented to eliminate waste at the storage locations in many large cities. CETY brings a solution to market that allows the producers to eliminate the disposal and transport costs before shipping waste to a large collection facility, while producing value added products.

Originally designed to fix the shortcomings of other Pyrolysis systems, the HTAP products use high temperature ablative decomposition to reduce the waste containing complex hydrocarbon chains into Hydrogen, methane, and other Syngas components and into biochar. This flash decomposition system eliminates the hard to handle and dispose of tars common to other Pyrolysis systems.

HTAP 5 and HTAP 10 allow for modular design and installation of a solution to handle 5,000 and 10,000 tons annually of any carbonic waste stream. These solutions handle dryer agricultural waste that digesters do not want. They accommodate woodchips, plastics, tires, and many other waste streams and convert that waste to sellable products: electricity, green hydrogen and syngas, and biochar.

Applications/Case Studies

The HTAD systems have been successfully applied to many carbonic waste streams and are ready for many more. Any application that starts with high carbon content can be decomposed to valuable products, reducing your disposal, transport, and tipping costs, while generating a revenue stream.A sawmill that produces 75 wet tones of wood waste every day, has installed the HTAP unit. They used to pai for handling, transport, and disposal of the waste. Now the waste is decomposed to ~1,500 Nm3/hour of syngas used to power generators that cover the onsite power demands. The biochar is sold as an additional revenue stream.

As part of the sunflower oil production, ~60 wet tons of sunflower plant and seed husks are produced each day. Historically the company paid for packaging, transport, and disposal of these wastes. Now, the waste is decomposed to 1,200 Nm3/hour of syngas and biochar. The syngas is used to power the onsite process boiler offsetting the operations fuel energy needs, and the biochar is sold as an additional revenue stream.

Used tires from passenger and commercial vehicles will continue to fill the waste management streams. The CETY HTAD system can decompose these hazardous items into usable syngas and inert biochar. This both eliminates the hazard posed by the decomposing tires and produces usable syngas and productive biochar.

Product Details

| Characteristic | HTAP-5 | HTAP-10 |

|---|---|---|

| Annual capacity (dry mass tons) | 5,250 | 10,500 |

| Syngas Production (% mass) | 70 – 95 | 70 – 95 |

| Biochar Production (% mass) | 5 – 30 | 5 – 30 |

| Annual Operation (hours) | 8,400 – 8,600 | 8,400 – 8,600 |

| Gross Electric Generation (kW) | 1,300 | 2,400 |

| Net Electric Generation (kW) | 1,000 | 1,800 |

| Scheduled Maintenance Interval (hours) | 4,000 | 4,000 |

| Scheduled Overhaul Interval (hours) | 60,000 | 60,000 |